Zhejiang Wenxian Gear Co., Ltd. | [email protected]

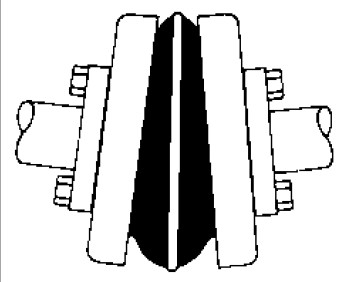

S-Flex Variety

Procedure

S-Flex Coupling Choice Approach

The variety course of action for determining the proper S-Flex coupling calls for employing the charts proven around the following pages. You will discover three parts to become chosen, two flanges and one particular sleeve.

Information and facts important prior to a coupling may be selected:

HP and RPM of Driver or running torque

Shaft size of Driver and Driven equipment and corresponding keyways

Application or products description

Environmental conditions (i.e. severe temperature, corrosive conditions, room limitations)

Actions In Choosing An S-Flex Coupling

Step 1: Establish the Nominal Torque in in-lb of your application through the use of the following formula:

Nominal Torque = (HP x 63025)/RPM

Stage 2: Utilizing the Application Services Aspect Chart 1 choose the support aspect which greatest corresponds to your application.

Phase 3: Determine the Design Torque of your application by multiplying the Nominal Torque calculated in Phase 1 by the  Application Service Element determined in Step 2.

Application Service Element determined in Step 2.

Design and style Torque = Nominal Torque x Application Services Component

Stage four: Applying the Sleeve Effectiveness Data Chart 2 choose the sleeve materials which most effective corresponds to your application.

Step 5: Working with the S-Flex Nominal Rated Torque Chart 3 locate the acceptable sleeve material column for the sleeve picked in Stage four.

Stage six: Scan down this column on the very first entry exactly where the Torque Value during the column is greater than or equal to the Design and style Torque calculated in Stage three.

Refer for the greatest RPM value of the coupling dimension to make certain that the application prerequisites are met. In the event the highest RPM worth is significantly less than the application necessity, S-Flex couplings usually are not recommended to the application.

Note:

If Nominal Torque is less than 1/4 of the coupling’s nominalrated torque, misalignment capacities are lowered by 1/2. As soon as torque worth is located, refer for the corresponding coupling dimension inside the 1st column on the S-Flex Nominal Rated Torque Information Chart three .

Step seven: Compare the application driver/driven shaft sizes to your greatest bore size obtainable to the coupling selected. If coupling max bore is not really large adequate for your shaft diameter, select the next greatest coupling that will accommodate the driver/driven shaft diameters.

Step 8: Using the Item Variety tables, obtain the ideal Keyway and Bore dimension demanded and locate the amount.