Zhejiang Wenxian Gear Co., Ltd. | [email protected]

How to Design a Worm Gear

Designing a worm gear can seem like a complex task, but with the right knowledge and understanding of the process, it becomes quite manageable. This guide will provide detailed information about the process of designing a worm gear, its features, and applications.

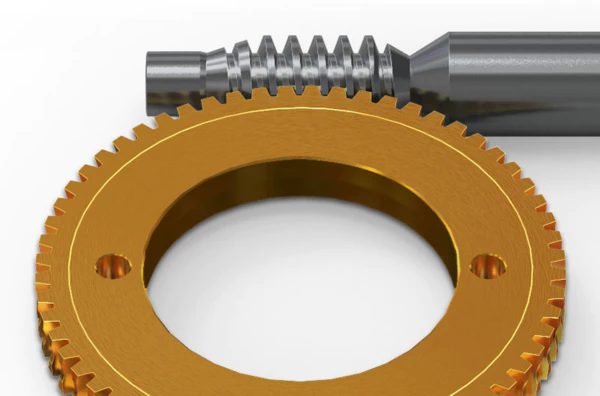

Understanding Worm Gears

Before diving into the design process, it’s crucial to understand what a worm gear is. A worm gear is a specific type of gear composition in which a screw (worm) meshes with a gear/wheel similar to a spur gear. The set-up allows the user to determine rotational speed and also allows for higher torque to be transmitted.

Features of Worm Gears

Worm gears are known for their unique features, which include:

- High Torque Capacity: Worm gears are capable of transmitting high torque.

- Right Angle Driver: They provide power transmission at 90 degrees.

- Decreased Noise: Unlike other gear systems, worm gears operate quietly.

- Non-Reversible: The gear cannot move the worm unless it’s at a particular angle.

Steps to Design a Worm Gear

Designing a worm gear involves a series of steps that require careful consideration.

Step 1: Determine the Load and Speed

The first step in designing a worm gear is to determine the load and speed requirements. This will help you define the torque and power requirements for your gear.

Step 2: Select Material

The choice of material for your worm gear will significantly affect its performance, durability, and cost. Commonly used materials include steel, bronze, and plastic.

Step 3: Determine the Gear Ratio

The gear ratio is the ratio of the number of teeth on the gear to the number of threads on the worm. It’s an important factor in determining the gear’s output speed and torque.

Step 4: Design the Worm and Gear

The worm and gear must be designed to mesh correctly. This involves determining the correct pitch, diameter, and number of threads or teeth.

Step 5: Evaluate and Refine Your Design

After designing your worm gear, it’s essential to evaluate its performance and make any necessary adjustments to improve its efficiency and longevity.

Applications of Worm Gears

Worm gears are used in various applications due to their ability to provide high torque output and precise speed reduction. Some common applications include:

- Elevators: They are used because they are non-reversible, which prevents the elevator from slipping down.

- Conveyors: Used due to their high torque and quiet operation.

- Printing Presses: The high gear ratio allows for precise speed control.

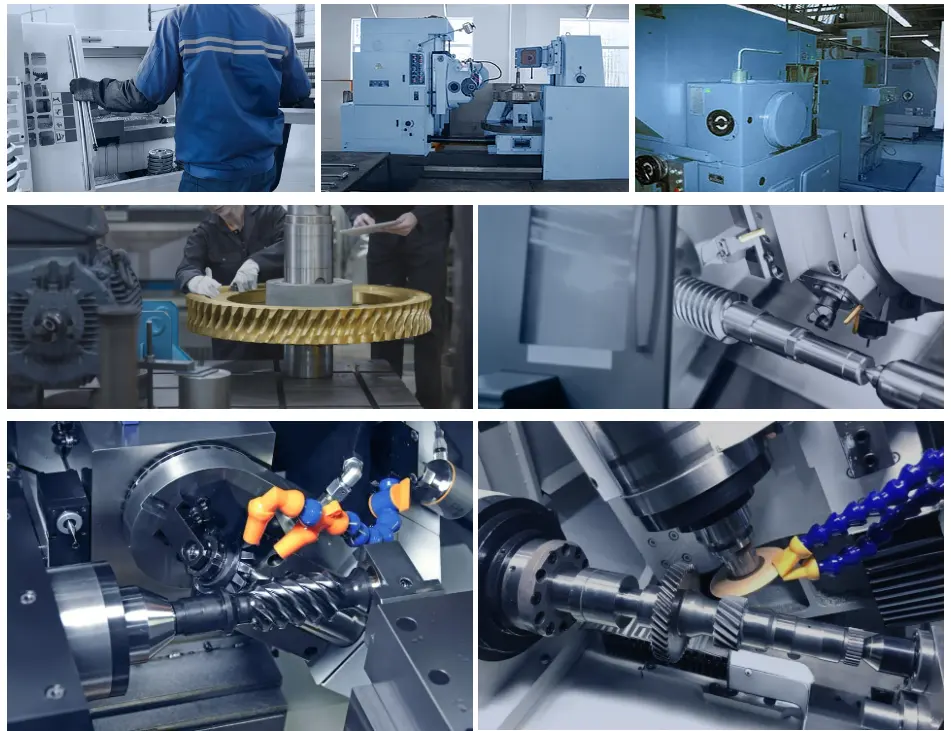

Why Choose Our Company’s Worm Gears

Our company offers high-quality worm gears that are designed for efficiency and durability. We provide competitive prices, excellent customer service, and quick delivery times. Our worm gears are made with precision and are guaranteed to meet your specific requirements.

Quality

Our worm gears are made from top-grade materials, ensuring durability and long-lasting performance.

Price

We offer competitive prices for our high-quality worm gears. We believe in providing value for money to our customers.

Service

Our team of experts is always ready to assist you with your queries and concerns. We believe in ensuring a seamless and satisfying experience for our customers.

Call to Action

Invest in our worm gears and worm gearboxes today for efficient, durable, and quiet operation. Don’t settle for less; choose the best for your machinery. Visit our website to explore our wide range of products.